Racing a Solar Car Across the USA

I get a lot of questions about my experience building and racing a solar car across the USA in 2003. So Here's some information and pictures from the experience.

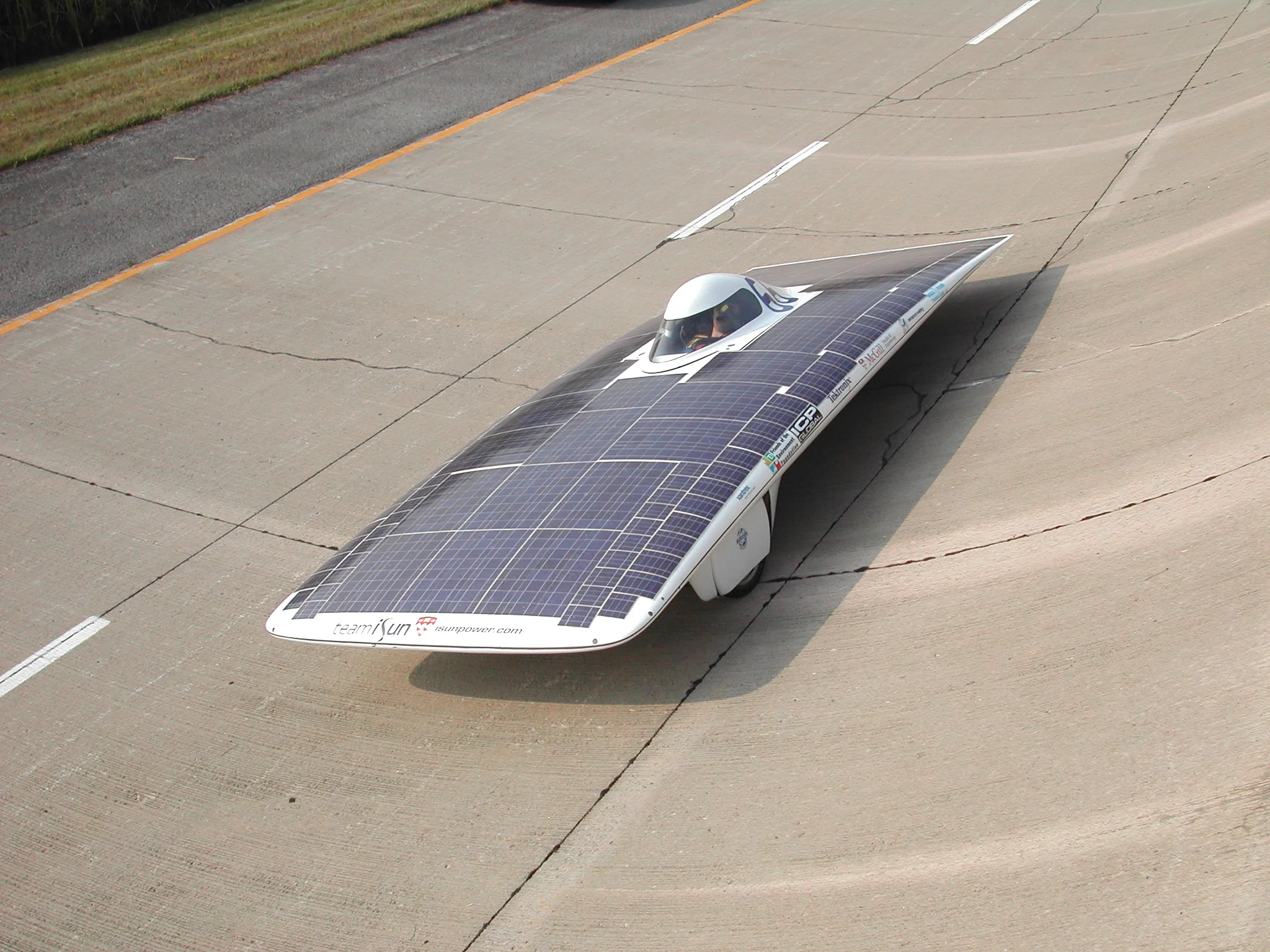

The iSun Solar car on the test track.

The iSun solar car in the California desert during the 2003 American Solar Challenge.

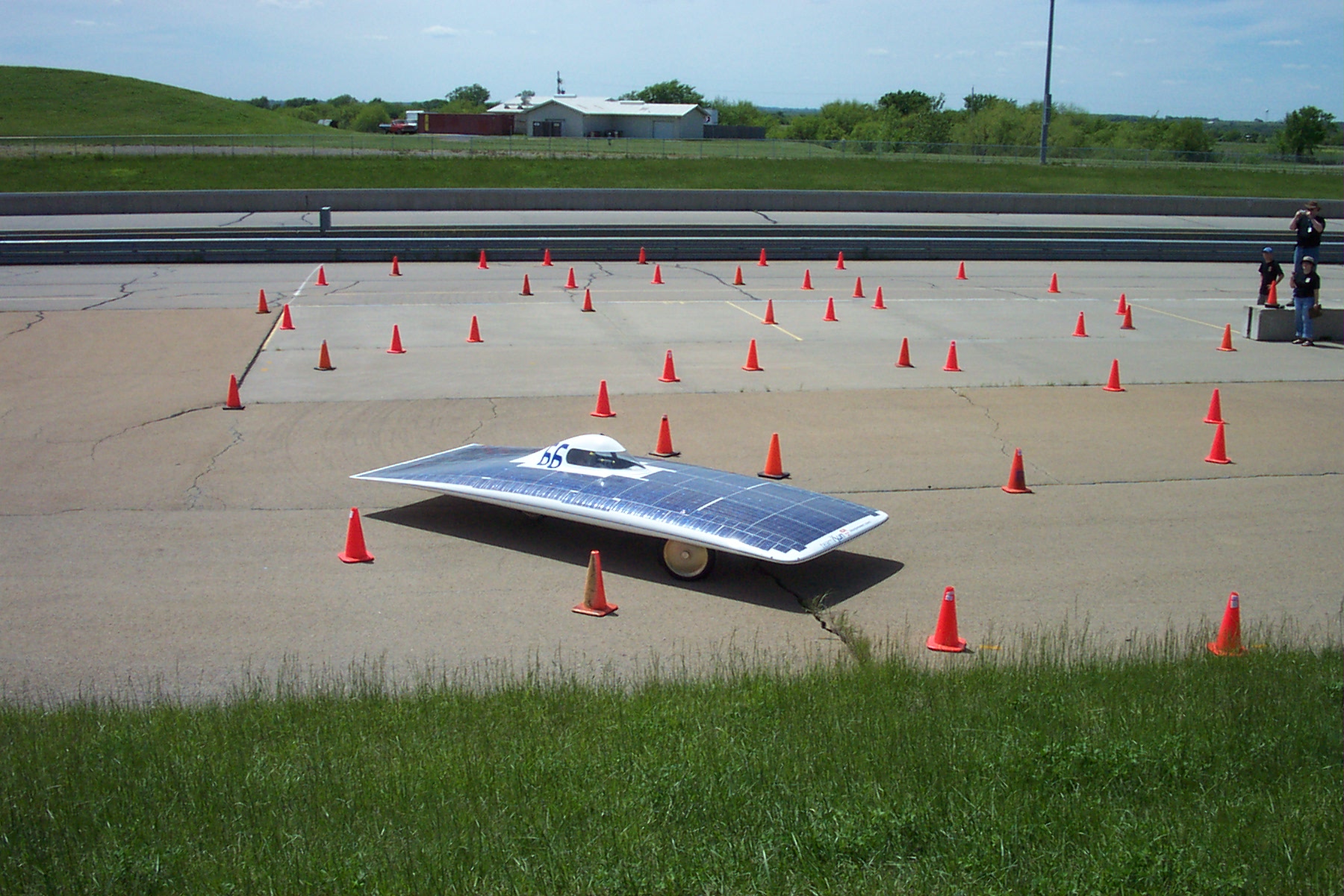

The iSun solar car prepping for the 2002 Formula Sun Grand Prix on the Canadian government test track outside Montreal Quebec Canada in 2002.

McGill University’s Solar Vehicle Racing Team was founded in 1992 when the team designed and built the first ever solar car in the province of Quebec. Between 1992 and 2005 the team participated in many international solar vehicle competitions, often doing well. My journey with the team culminated in the 2003 American Solar Challenge from Chicago to Los Angeles as featured in the video below.

In 1999 the team dissipated after a successful run at the World Solar Challenge in Australia. I joined the team in 2001 after I became bored with my classes at McGill and there were only 3 or 4 of us on the team at that time. Regardless, I wanted to use my new engineering skills to build something real. Over the next 3 years the team grew and my 'solar car buddies' and I designed, built and raced McGill's third car, which we named iSun.

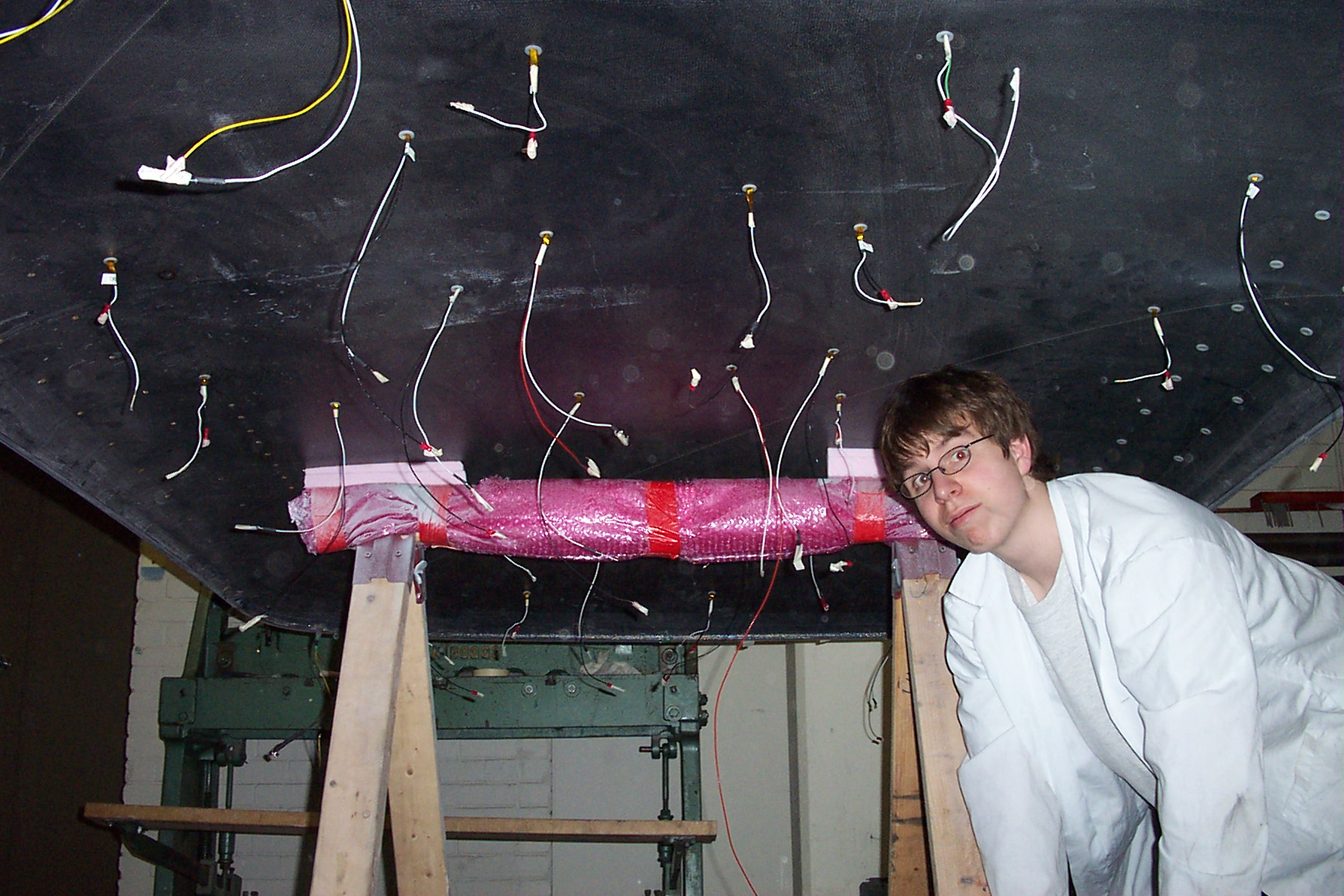

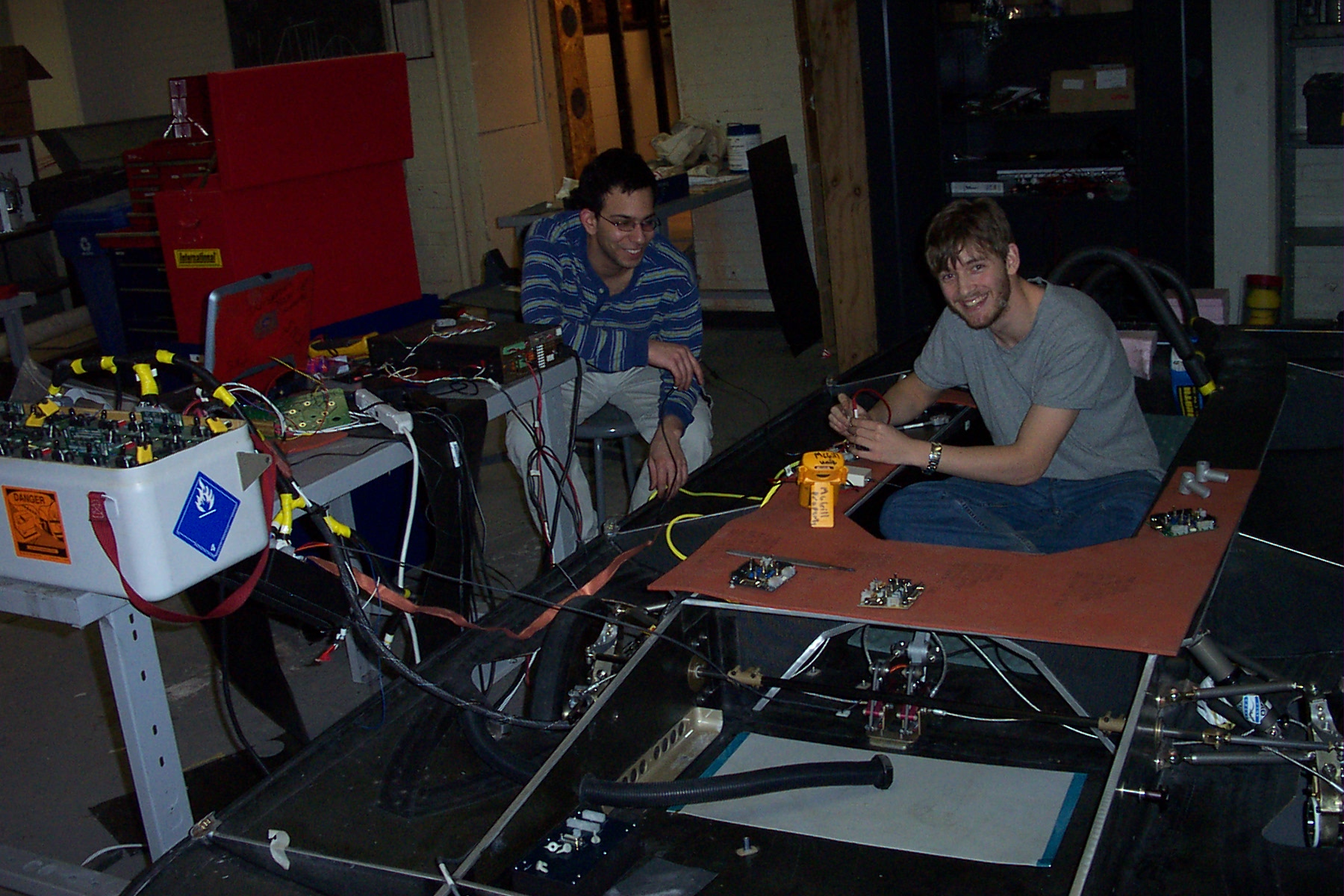

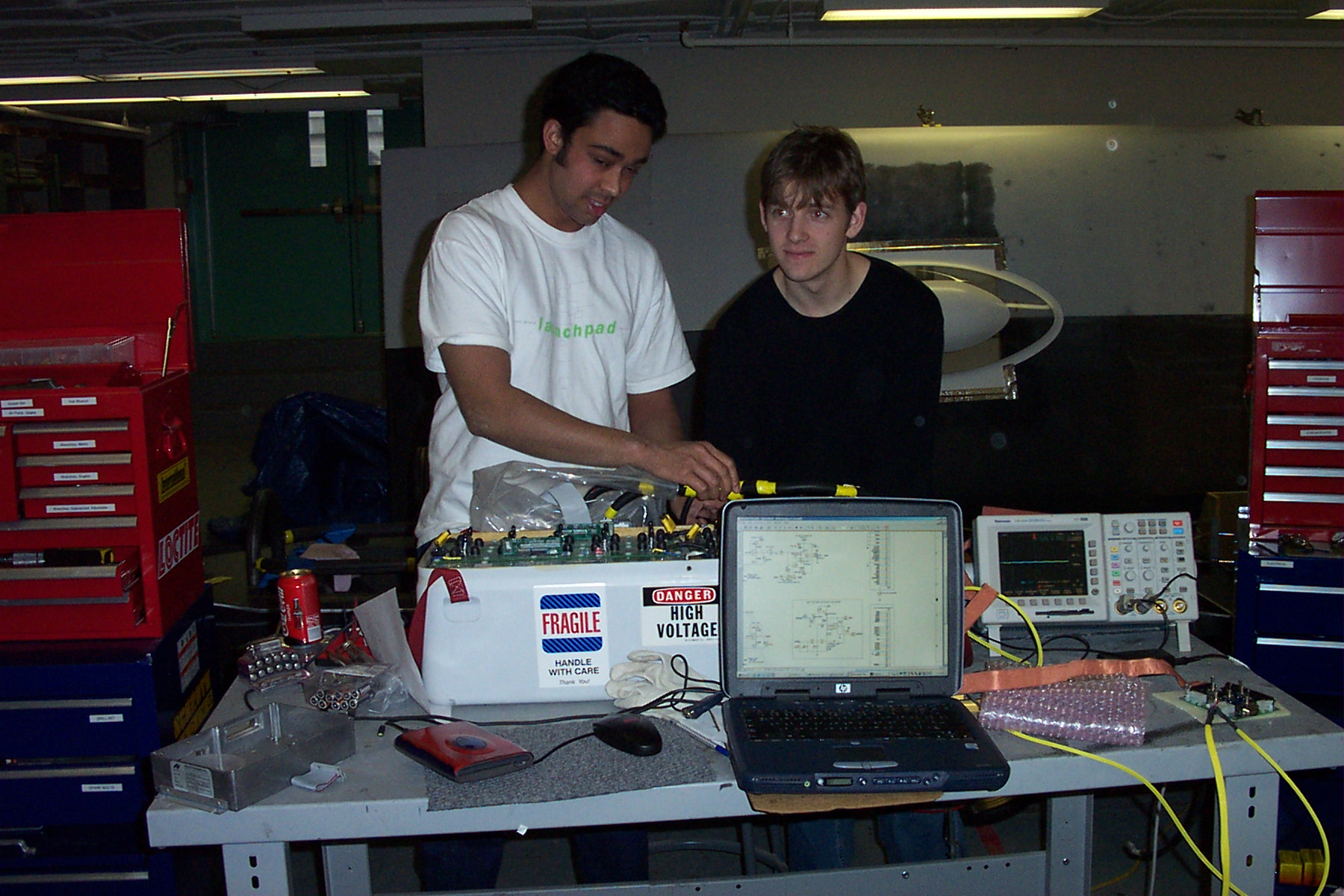

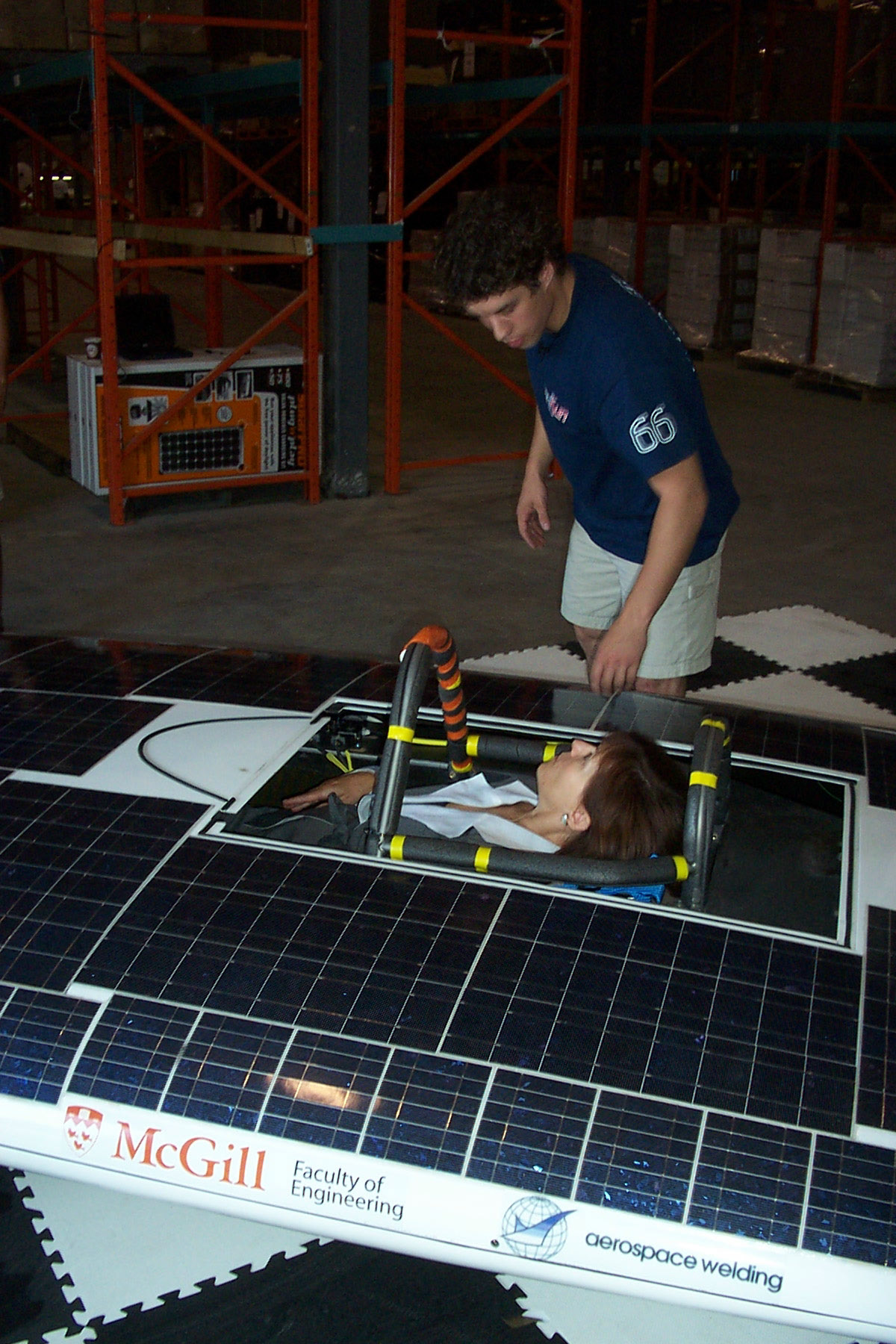

Formula Sun Grand Prix

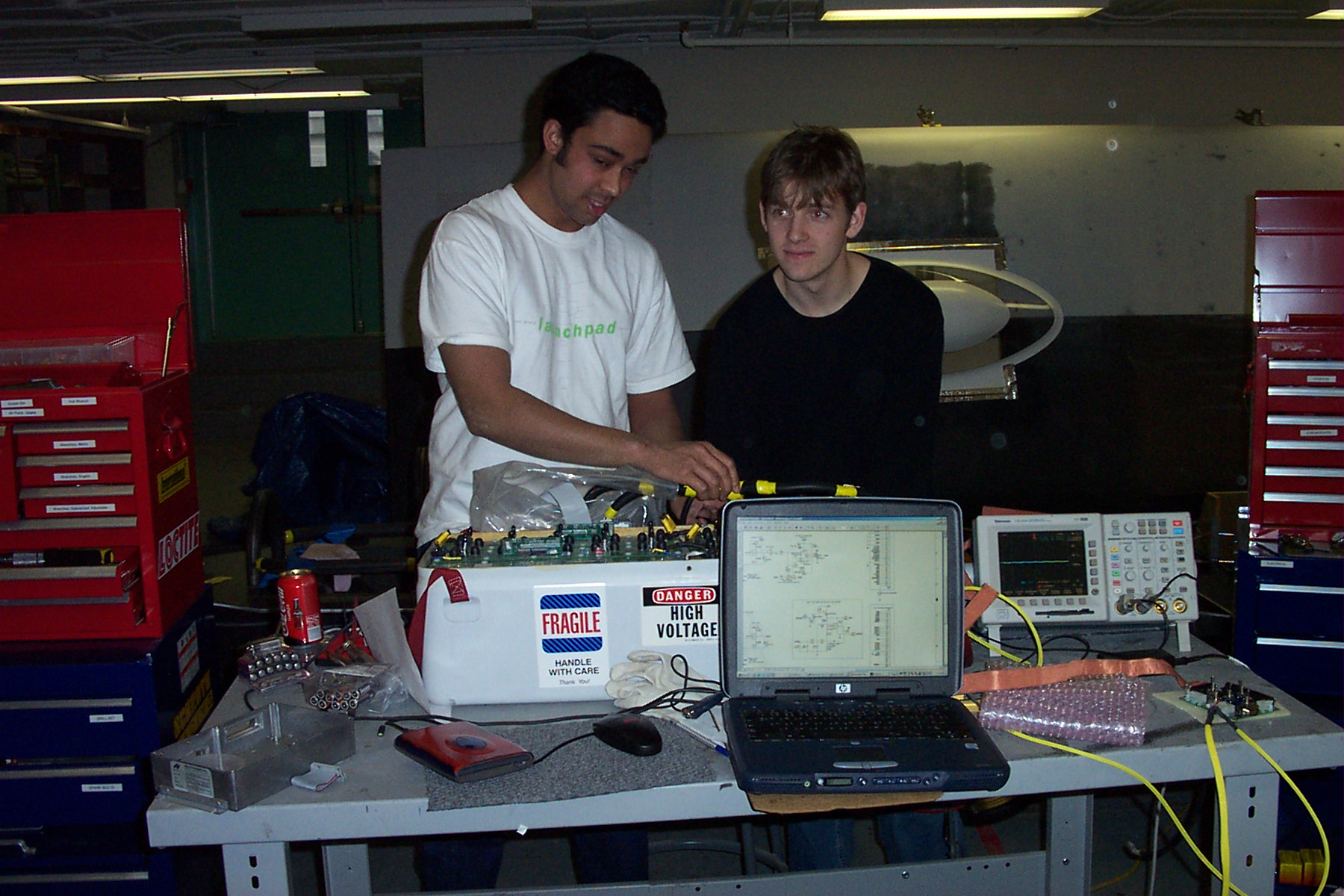

One reason the 2003 American Solar Challenge was such a success for McGill and for all of us on the team, is that our team had failed to qualify for the 2001 American Solar Challenge. After a year of work, and a trip from Montreal to Chicago, an electrical short in our hastily assembled solar array had ended our run before it even began. We returned to Montreal licking our wounds and decided to aim for the next race: the 2002 Formula Sun Grand Prix, a track race in Kansas. Some of my favorite memories from this time relate to solving problems and building cool stuff with my friends on the team as shown in the gallery below.

After a year of regrouping, we made it to the Formula Sun Grand Prix, qualified, and finished the race. This put wind in our sails to once again attempt a full cross-country race 2003.

2003 American Solar Challenge

By 2003 our team had gelled and we had worked out enough problems with the car that we were pretty confident we'd be able to finish the race. the race began in Chicago at the Museum of Natural History. Thousands of spectators and members of the media were present to witness the start of the race.

Lined up for the starting photo at ASC 2003

iSun lined up with the others in the field at the start of ASC 2003

The 21 teams qualifying for the race were released one minute apart as each team began its race against the clock to reach the next checkpoint in the shortest time.

The iSun solar car on the right next to the car from Missouri-Rolla on the left.

After leaving Chicago we raced all day and ended up being taken in at a local airport to spend our first night. Generally the solar car was treated as a curiosity and opened doors for us wherever we went.

Matt Smith looking over telemetry on the car as Simon looks cool and the sun sets.

The race followed historic Route 66 from Chicago to Los Angeles, and took us through cities and country, plains, forests, mountains and deserts.

From the cities of the midwest into the arid plains of the West...

We had a couple roadside breakdowns, where we'd hit a bump and the car would stop working. We'd pull over and scramble to figure out what was going on. As a driver I'd take the chance to go find a place for a bathroom break.

Roadside breakdown. Thank the universe for the Easy-Up.

From dawn to dusk, we drove all day every day.

At 6pm each day we had to pull off the road wherever we were and make camp. We'd set the array on it's charging stand and use the last waning rays of the sun to store some extra electrons in our battery pack for the next days racing.

iSun array charging after a day of racing.

As one of the drivers of the car, I soon realized that a vehicle built to absorb the maximum amount of solar energy is damn hot inside! Then I realized that I had begun to sweat, a lot. And then I realized that the shell of the car was conductive and that my salt-infused sweat had begun to pool in the cockpit of the car. Yikes.

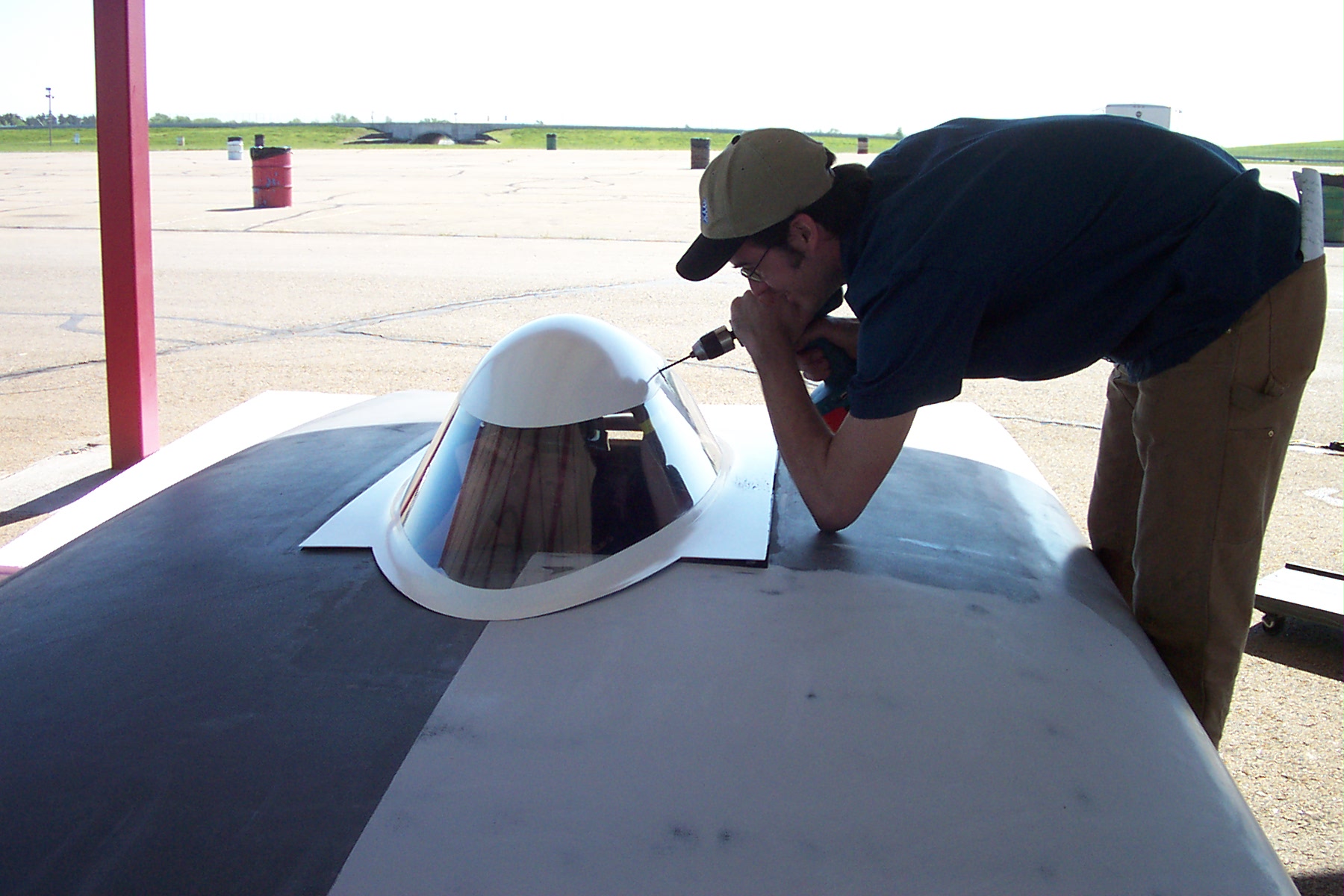

At the next checkpoint I frantically called for a drill and put some quick "speed holes" in the bottom of the cockpit so my sweat could drip out and I wouldn't get electrocuted through my sweat shorting a part of the electrical system.

Me (Will Sacks - left) and Nick Verzeni during the 2003 ASC. We drove the car in shifts from Chicago to Los Angeles.

The race went extremely well for Team iSun. We experienced approx. 9 hours of down time over our 74.5 hours of time on the clock. After ten days of racing, and 2300 miles later, our car crossed over the finish line of the American Solar Challenge in Claremont CA on the morning of July 23rd 2003.

Len with iSun at the finish line

Team iSun finished 2nd of all cars with Silicon solar cells (vs. the much more expensive gallium-arsenide cells on the best funded cars), and 9th overall out of the 31 cars that registered for the race (20 qualified). We had entered the race as underdogs and were extremely happy with this result. In addition:

- Team iSun won the silver medal for Best Overall Vehicle Design and the Gold medal for Best Mechanical Design.

- Team iSun also won the award for the Best Rookie Team, Most Elegant Design, and the Teamwork Award.

- In all, Team iSun won more awards than any other team

Our team from left to right: Matt Masicotte, Simon Dandavino, Nick Verzeni, Matt Smith, _, Caroline Lau, Will Sacks, Emilie Fortier-Famelart, _, Philippe Chaput, Jean-Francois Robataille, Phil Weicker, Dan Sufrin, Leonard D'Cunha, Joel Robert. Not pictured: Matthieu Roberge, Mike Tolley.

American Solar Challenge Race Diary

Within the group of seventeen people attending the race, team members were divided between a Logistics team, Electrical team, Mechanical team, Sponsorship team. Being the lead of the sponsorship team, I was basically useless during the race except to drive the car. So my friend Nick and I split the driving, each doing 3-4 hours per day as we snaked across North America.

After the race, we interviewed everyone on the team to get some lessons learned and perspectives for history. Here's a little insight about what it was like to be on the inside of this project, as well as some tips from the team:

Words from the team:

"SLEEP : Barely sleeping during the three days before the departure is a very bad idea. Although the drivers from Montreal to Chicago did get some sleep the night before or that same day during the trip, bad surprises on the road could have been very costly. Organize driving before leaving, not only should the drivers be designated for approximate time shifts, the co-pilot should also be chosen before hand. This allows everyone to try to get the sleep required. Also although a constant structure ensures that things run smoothly and allows people to learn from their mistakes, members only learn about one part of the race." - Caroline Lau

"Design things that are impossible to hook up wrong. If connectors can be plugged into the wrong places, this will happen. Keyed connectors can stop this from happening so only keyed connectors should be used".

During the race we had a lead vehicle (the red van seen ahead) and a chase vehicle. For those in the chase vehicle, this was the sight for days.

"The best thing I can contribute, is how the team was organized, how it is organized, and how that can affect the building and racing of the car. Timelines: Proper timelines need to be made, and visible to everybody. The more you allow people to either help with a project (if they are capable) or the more you explain how something will work, and why certain decisions were made (for those not as experienced), the more they will feel they own the car. The more they feel they own the car, the more they will be willing to work on it. Despite the stress, the long hours , the blood sweat and tears, this can be one of the most amazing experiences of your life." - Dan Sufrin

"FOOD: First I have to urge that a girl AND a guy take care of buying the food, minimum AND maximum. First, because it avoids buying to many things that we don’t need." - Emilie Fortier Famelart

"The theory you learn in class and the real life application of this theory are two different worlds."

"We start with scrutineering. This is by far the most stressfull period if you car isn’t fully ready and tested and this is applicable to every race you go to. This is the time where you will work non-stop until the damn thing works. For many teams, (10 at the American Solar Challenge) this will be the first and last days of the race. Before going to the race, make sure you have reviewed the scrutineering guidelines to know exactly what is expected of you, and also have an engineer inspect your car according to the guidelines and see if you pass. " - Jean-Francois Robitaille

"Race time was for me the best place to learn how to manage a team, or at least how to not manage a team! Having the car on the road or on the test track is the only way to prepare for a race and know our car. It is very important that I learn to trust people to accomplish a task, even if it means spending twice as much time on it in order to build a team as we build a car. " - Joel Robert

"I would say that there was a fairly large list of things to get done before the race. But, I think that when it was first made, the list was quite manageable. It really was the fact that many things started going wrong, and the list never got shorter, it just changed. The race was a hectic time, for sure." - Matt Massicotte

"I was constantly told to get involved. In the Dean’s speech, from old students, in the newspapers; everywhere: 'Get involved'. I saw some posters of the solar car in the McConnell building and I thought it looked cool and interesting. I was happy with how things went; I think we weren’t that bad as a team. Always stopping to fix the electric system, that sucked. This race was also a great opportunity to meet other teams. Finally I got to see other solar cars up close. Teams helping each other, sharing (like tools), it’s just great. " - Patric Demers

"Our esteemed leader knew what it was going to take to qualify for the race, after more than an hour emotionally charged debate, a vote was called. The result was 13-1: we were going to Chicago. There were team members who hadn’t slept more than a few hours throughout the week, but they couldn’t start resting now. I don’t think that I’ve ever seen a group of people more motivated and more charged to succeed than I did leaving that meeting. Nobody slept that night or the next day, as batteries and circuit boards were tested, brakes were calibrated, and the daunting task of packing up hundreds of thousands of dollars of equipment to bring with us was undertaken. Make sure that there is somebody on the team that knows where everything is. You’re going to be living out of vans and a trailer with thousands of pieces of equipment stashed away. Hours can be saved with good packing. " - Paul

"In this race, Team iSun did great, considering our experience (close to none) and solar array. However, we could have done better. Also, gettinaccurate power vs. speed data would be very nice. Keeping the speed constant not only keeps efficiency up, but also makes strategy program simulations one step closer to reality (which is still pretty far). But strategy also has to account for hills, and may therefore include regen[erative braking]." - Philippe Chaput

"We did it. For the first time ever, McGill has participated in the American Solar Challenge. Not only did we participate, but we also gave an impressive performance. It started with the Mechanical Design award just after scrutineering and finished with the Second best overall design, best rookie team and clean car award. We ended up 9th out of 20 teams. This is fewer teams than ever, but, considering that all the race records were beaten, this did not make the race any less competitive.

Since I was in charge of testing this year, I guess I should say a couple words about it. In many aspects this year, testing was a failure. We could not, as we wanted, characterize the efficiency of the car at different angle of attacks, tire pressure and gap settings. Work for it and go. It’s worth it. Plus you’ll get to surf in L.A., gamble in Las Vegas and trek in the Grand Canyon. Actually, it might be a different route, but still, you’ll find something cool to do." - Simon Dandavino

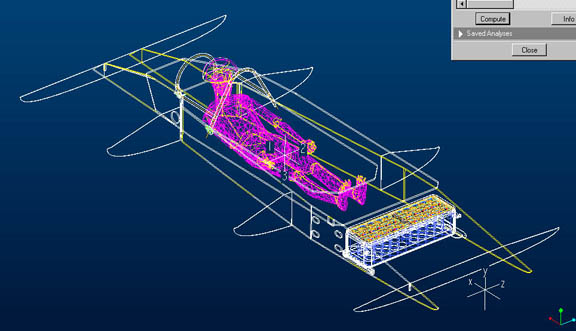

iSun Car Technical Details

Now getting down to the specs...

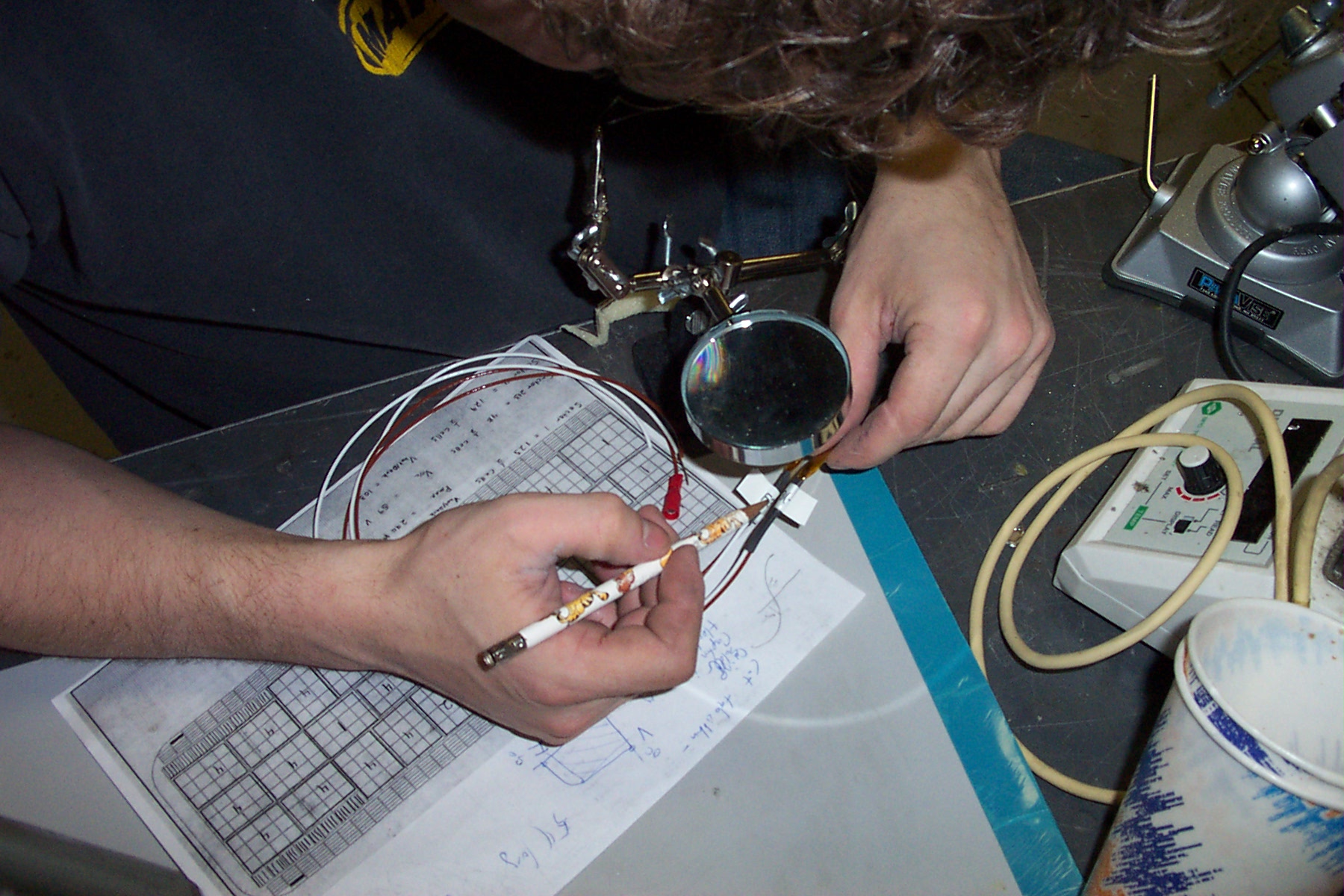

Although iSun underwent many changes since the 2001 American Solar Challenge, the basic layout of structural and aerodynamic features remained relatively constant. Some pictures of components, construction and testing are below.

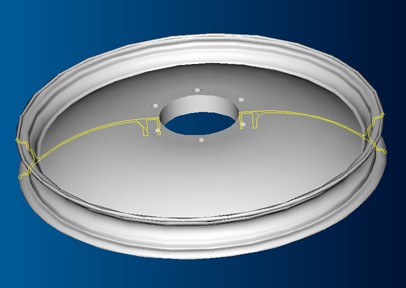

Canopy

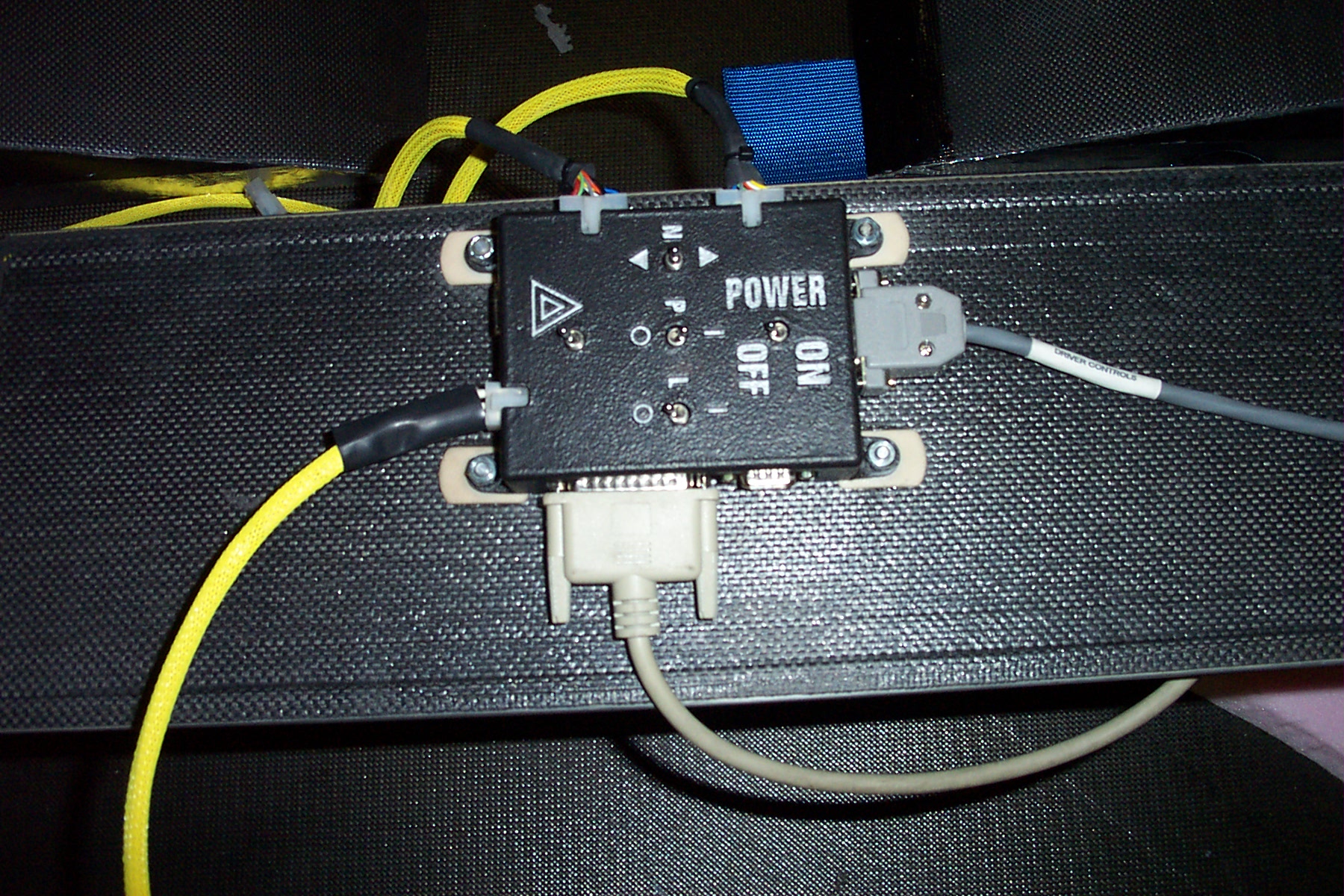

The car continued to utilize the three-wheeled configuration and a ‘bubble–style’ canopy with lexan windshield. The previous carbon fiber canopy was replaced with a kevlar model, in order to improve transmission of telemetry data (the carbon fiber was conductive and scrambled the signal).

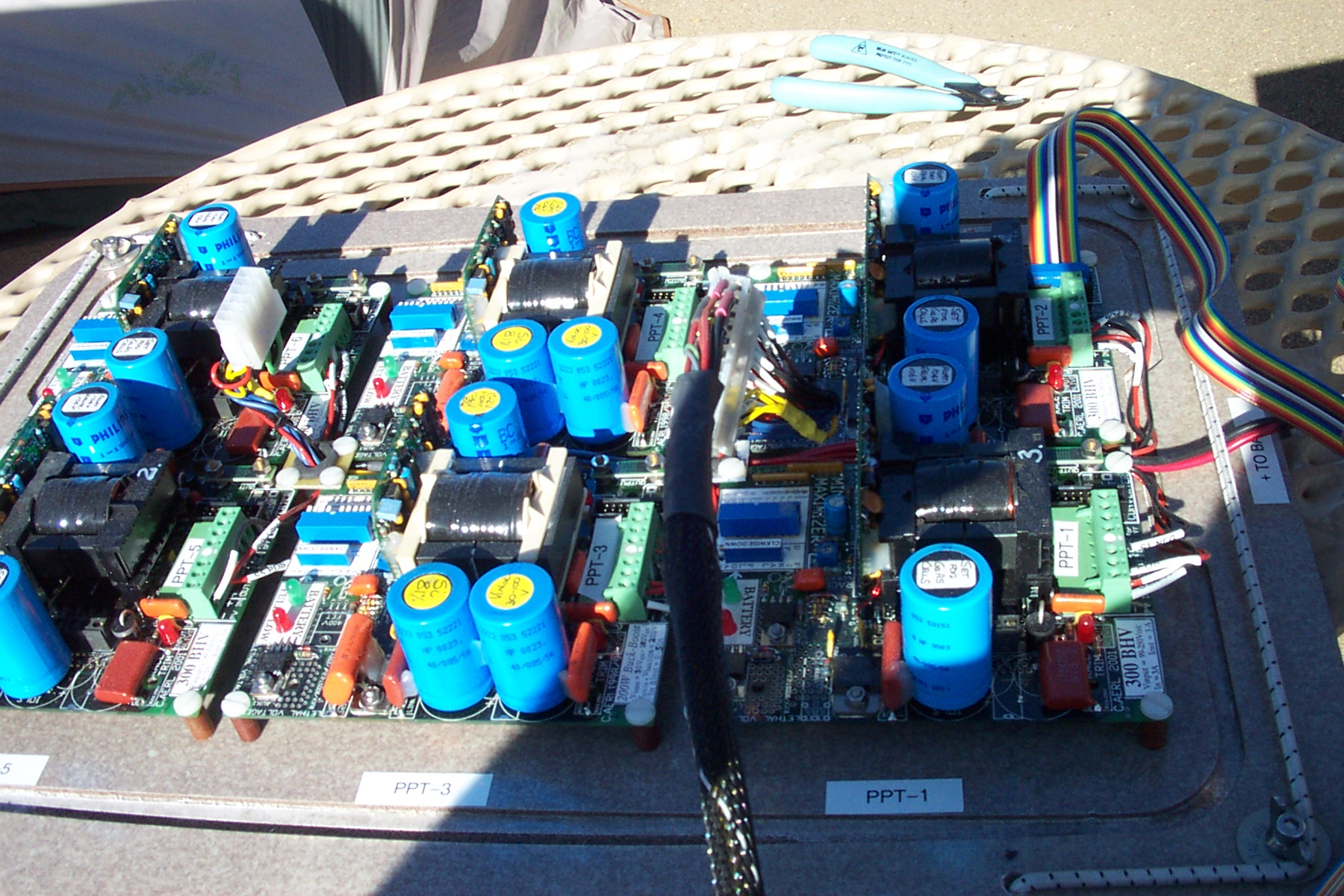

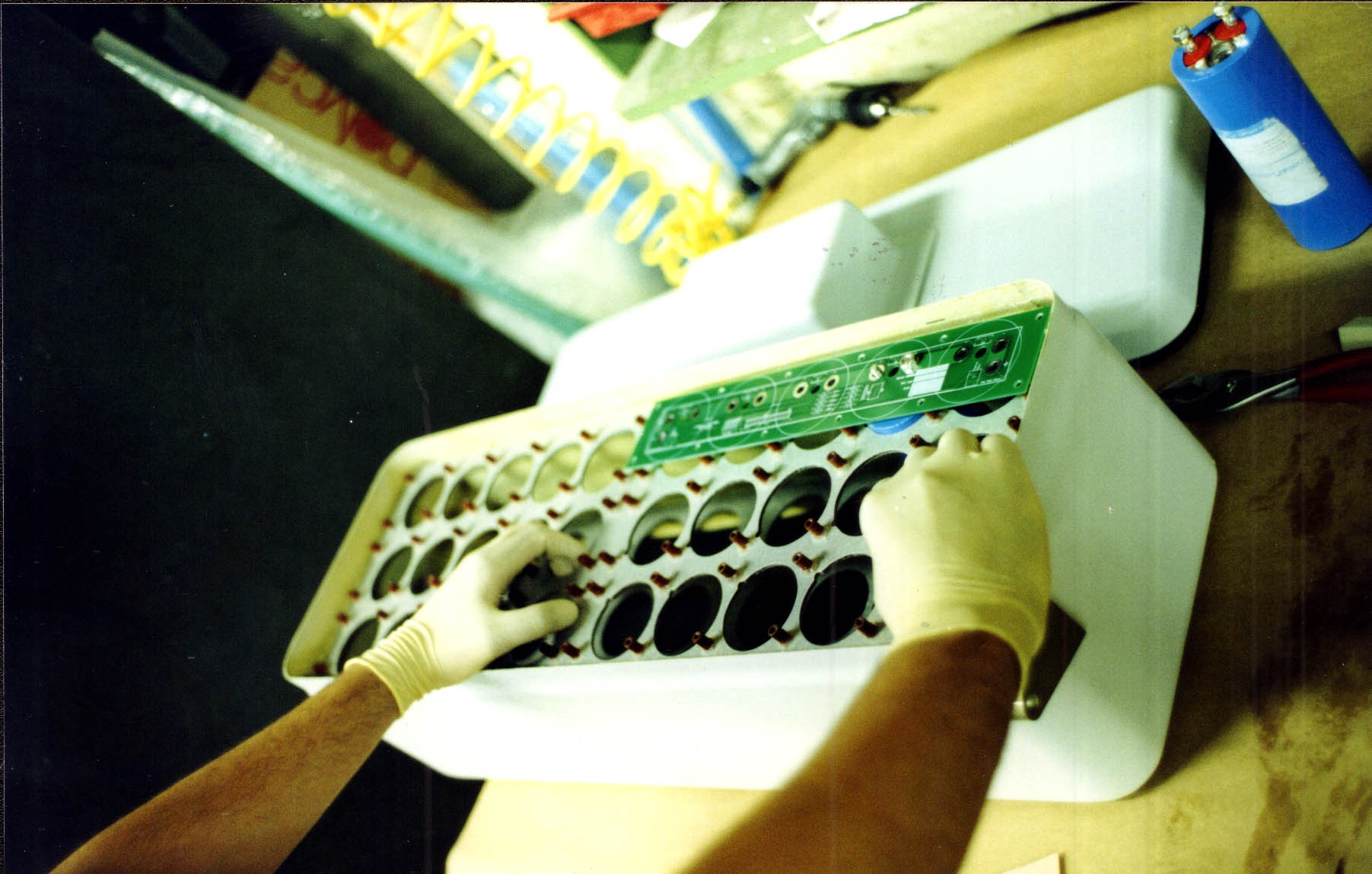

Battery Pack

The battery pack consisted of hundreds of lithium polymer cells and charging circuitry. For optimal safety, the battery pack was housed in a removable, non-conductive, impact resistant Kevlar box that was firmly attached to the front of the chassis during racing.

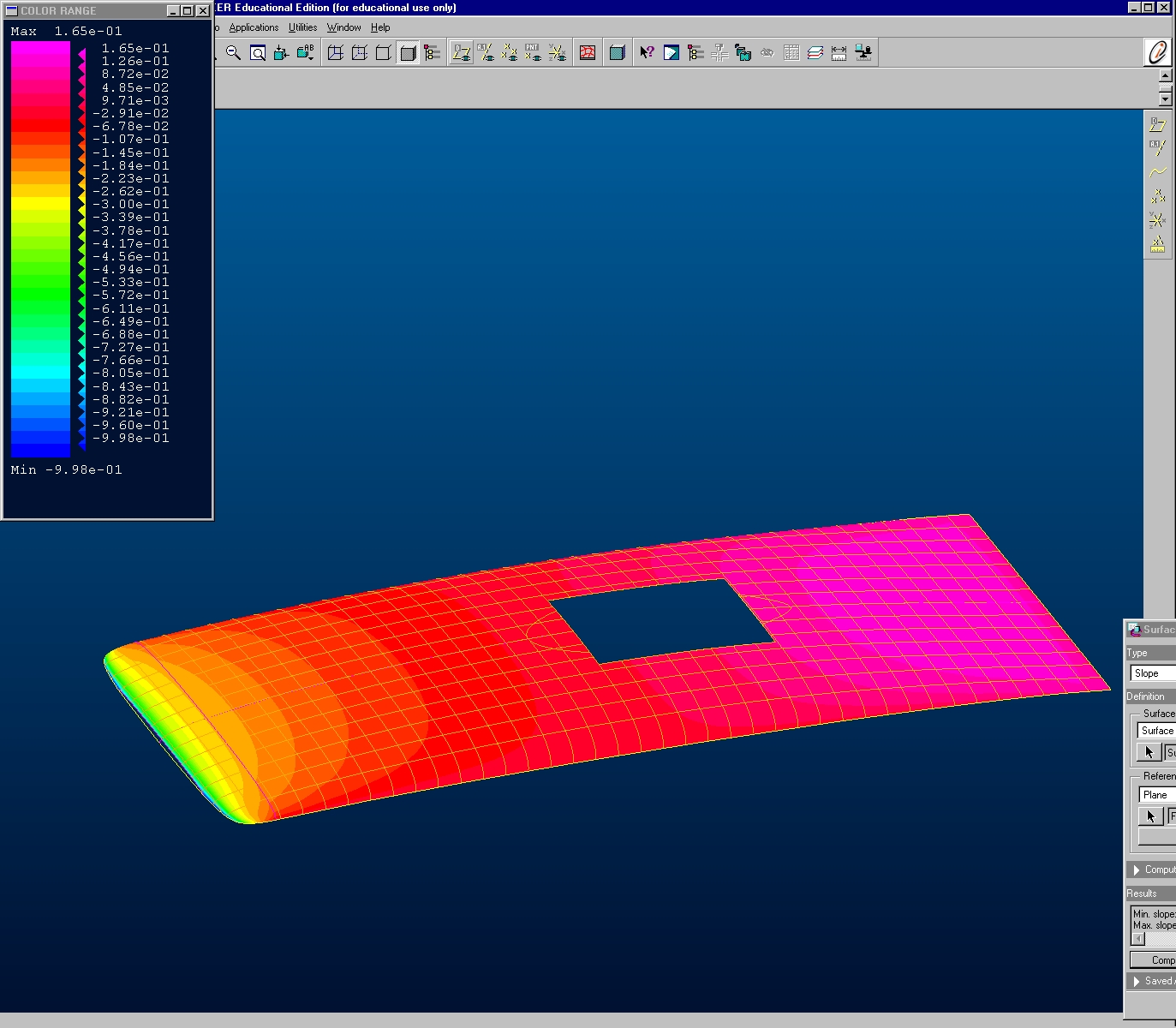

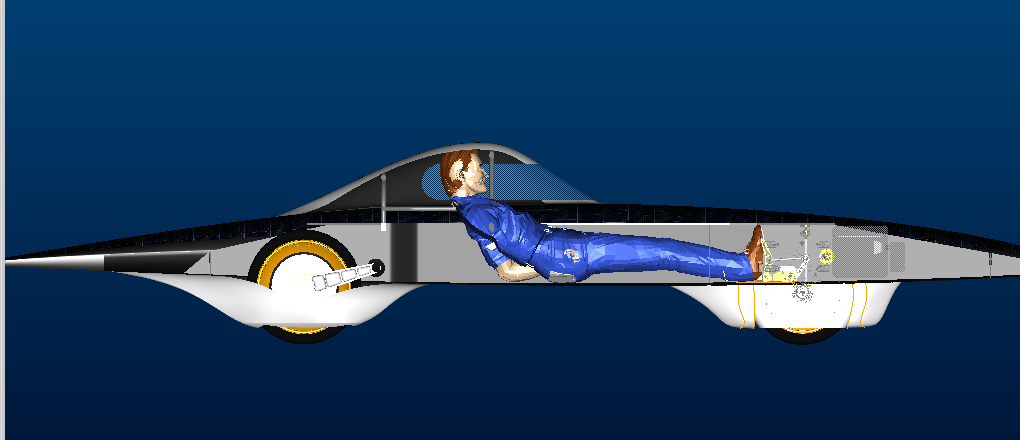

Driver Position/Weight Distribution

At one point we realized that moving the driver further forward could improve our handling and probably reduce rolling resistance (we ended up with too much weight on the rear tire). This problem also arose from the fact that the car was designed to accommodate a 6 foot driver which is not at all a necessity. Other teams design for a 5’5” driver or smaller in order to have more precise weight distribution with the accompanying ballast.

Ride Height

The current version of our car has a disproportionately large canopy. It's possible that reducing the size of the canopy could realize the greatest gains in improved aerodynamics for the car. Unfortunately, since our car is so low to the ground, and our air-foil is so thin, this canopy is necessary to meet the minimum driver eye height requirement of 70cm.

Front Track

We would have liked to be able to incorporate full front fairings over the front wheels to reduce drag. The limiting factor is that the wheels are so close to the side of the vehicle, that when turning to pass the figure eight test, the apex of the wheel almost leaves the shadow cast by the car. It might be possible to still incorporate a full fairing, but it would be hard to interface it nicely with the shell. For the future, I would suggest designing the fairing with the shell and molding them together, or as two separate parts.

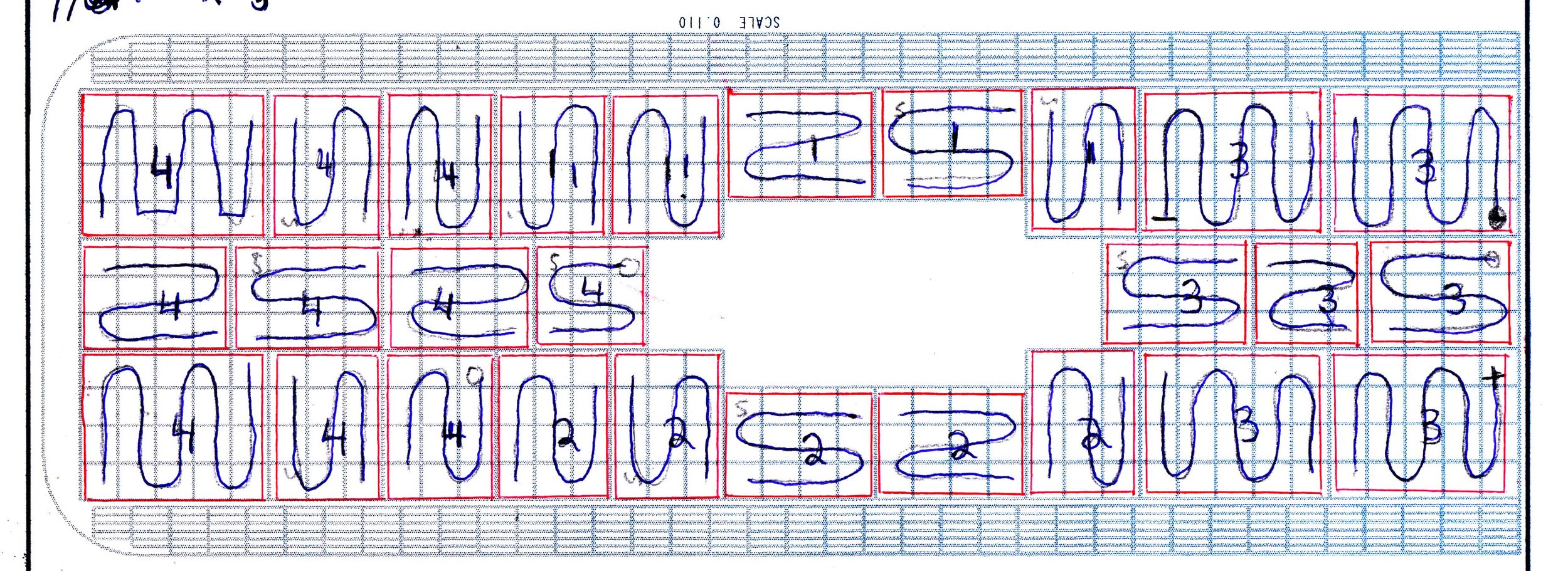

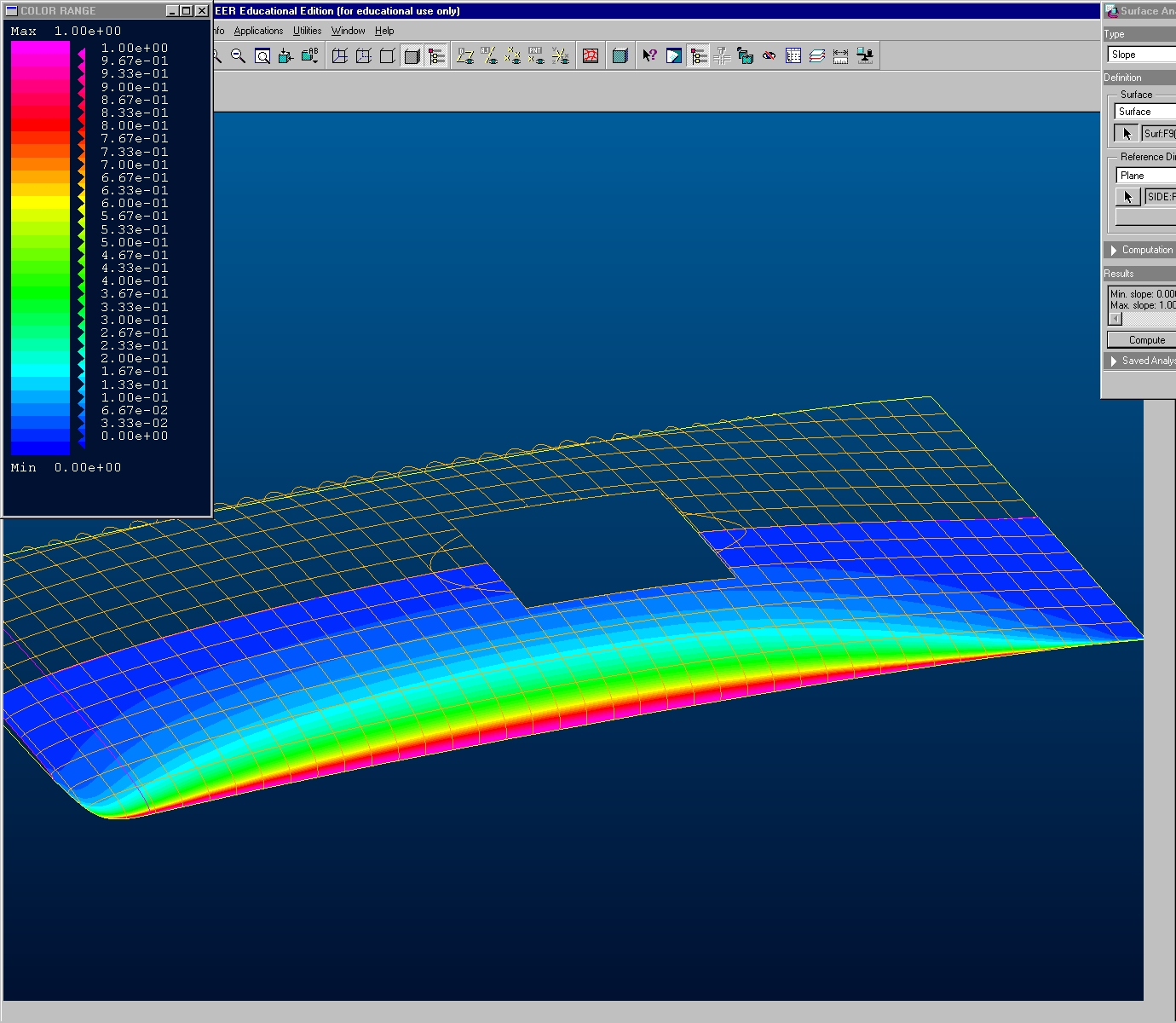

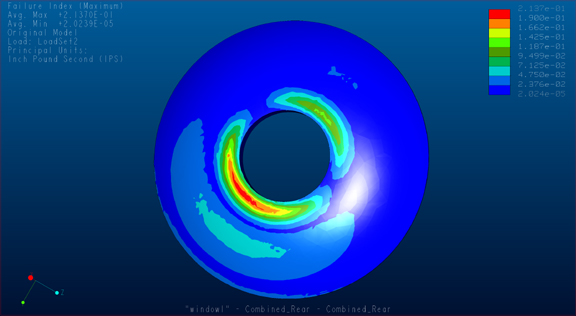

Solar Array Design

I designed the current solar array in a hurry. Basically the process was to first determine how many cells would fit on the car. We had our modules encapsulated by SunCat solar (who charges for each different size or module and for cutting cells as well). The challenge was to use as few module sizes as possible, and to cover the car with as many cells as possible. I used a mock up of the top shell totally covered with cells and drew modules over it. I settled on 6 sectors of modules, one in the front with a buck tracker, one in the back with a buck tracker, one on either side of the canopy with a boost tracker, and one up either side with a buck tracker (Buck and Boost refers to the maximum power point trackers that operate each module at peak efficiency given the solar load).

Obviously the challenge is to make sure your boost trackers will always be boosting (sector voltage always below battery voltage) and your buck trackers will always be bucking (sector voltage above battery voltage). This makes the layout more complicated as you have many variables to consider. we interconnected modules under the car which makes for easy maintenance, testing and the option to change the configuration of the module sectoring if we choose.

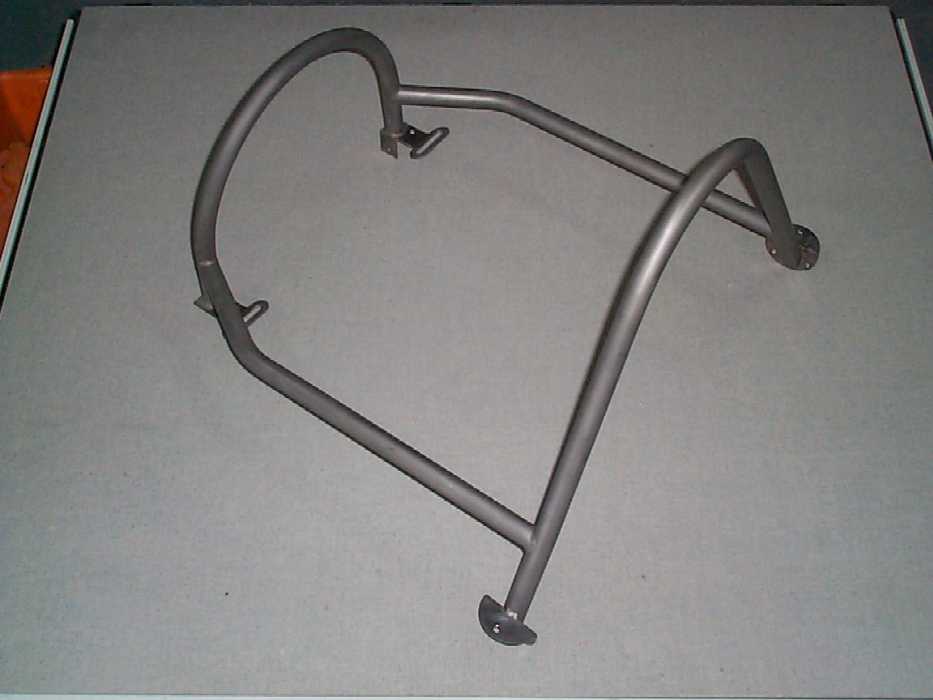

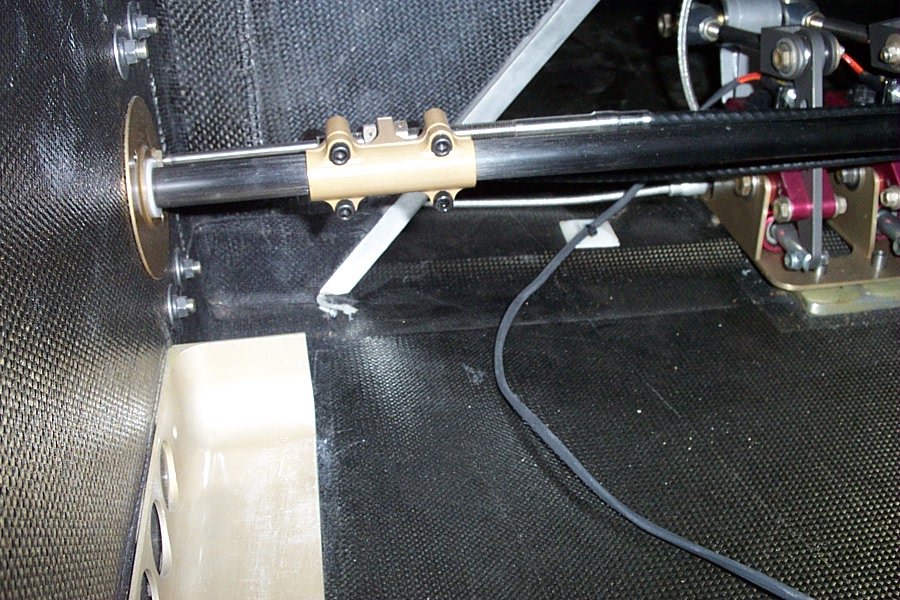

Brakes Design

The method of designing the brakes was a bit suspect. Instead of looking at other solar cars, we picked a friction co-efficient for our brake pads and calculated the force necessary to stop with the required deceleration (plus a safety factor). We then calculated the braking force that this would require from the driver. Having no actual test data made us end up with a design that was way overbuilt. It takes little effort from the driver the lock up the brakes with the current 9:1 ratio of pedal force to master cylinder force. We could probably do with 3:1 and save around 1 kg in the master cylinder brake linkage.

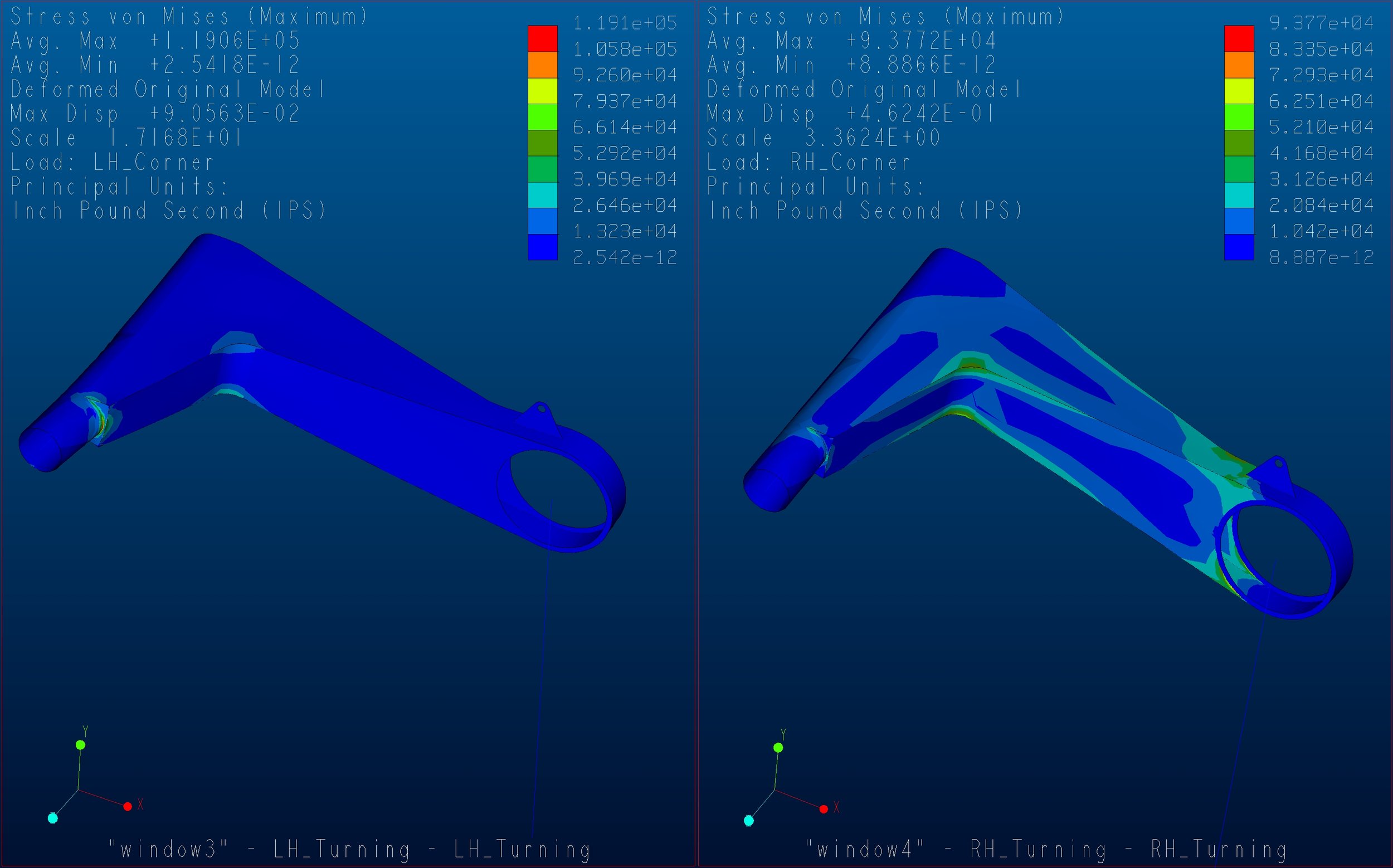

Steering

We originally used Lear Jet gearboxes and cables from Aeronvironment for the steering system. However, we found the cables gave too much friction to the system and prevented self-centering of the steering system. In testing we found self-centering steering to be a very important safety consideration–especially with the sensitive steering in the solar car. Self-centering also decreases driver fatigue as the solar car will tend to go in a straight line with little effort from the driver. The friction problem was solved with new (regular) cables and with breaking in of all the rodends in the steering system (ie. Putting them in a drill and wearing out some of the lining!). A third cable around the driver was pretentioned to get rid of the remaining backlash and we were off to the races.

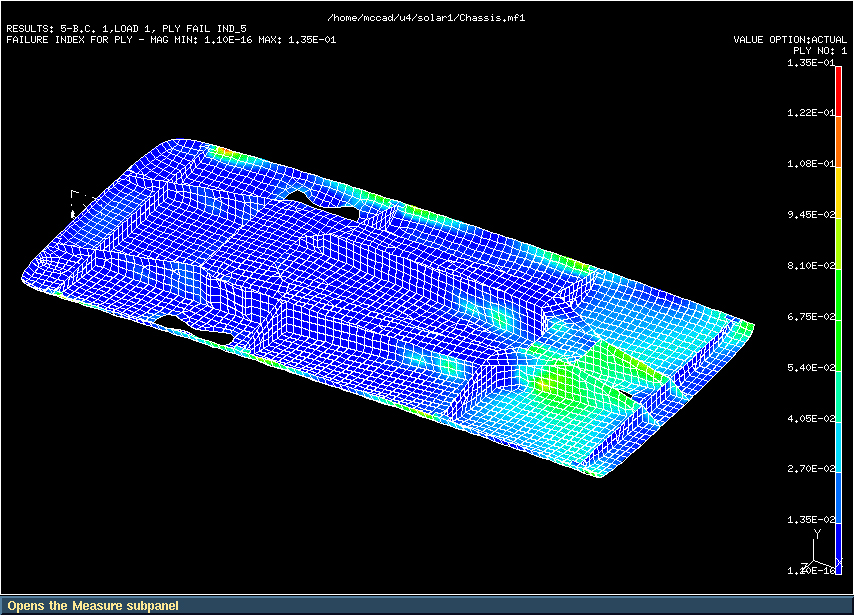

Chassis Construction

We ran out of nomex honeycomb at Bell Helicopter and so we had to use Aluminum for the top plate, this added some weight, but also some resistance to dropped tools, elbows and knees. All the hard points for the suspension, and battery mounting were reinforced with solid kevlar blocks, surrounded by putty (instead of, and filled into the honeycomb respectively). Also all the hard points were reinforced with extra plies of carbon and sheet adhesive. We had real problems with leaky molds for the side beams and shells.

We made the molds directly from an NC at Formglass instead of having them machine a plug. This resulted in the foam and plywood molds warping in the oven and making leaks which resulted in poor adhesion of the plies to the core. I would rather have made plugs at Formglass and made chopped fiber molds from the plugs. These molds are cumber some, but they last forever. To stick the chassis plates together we conducted some tests with wet layup carbon and methacrylate adhesive. A bead of adhesive proved to work extremely well and the test plates failed at the carbon just above the bead. The final design used a mechacrylate bead with wet layup carbon over it and has proved to work well. A black magic marker was used to color the wetlayup and is a large part of the reason that people say our car looks so nice!

Top and Bottom Shell

The top shell consists of a 3K plain weave carbon prepreg laminate (1 layer per side) sandwiching a lightweight 3/8 ” nomex honecomb core. The chassis and bottom shell, have been joined together as one structural component. These have also been constructed of the same 3K plain weave prepreg carbon fiber over both 3/” aluminum honeycomb (with core-bonding sheet adhesive) and 1/” nomex core, depending on the structural requirements of the region in question. Chassis ‘hard-points’ were reinforced with solid Kevlar 285 layups 3/8” thick to resist the out-of-plane compressive stresses resulting from tensioned bolts.

The bottom shell is reinforced under the drivers ass and is otherwise very light weight (1 ply either side). The top shell is made of carbon and this is the reason for the array fire in 2001. To prevent against this problem in 2002, much care needed to be taken with the wiring and installation of modules on the top shell. The whole job ended up with the array being much heavier than originally intended. I would avoid carbon for the future–many cars have kevlar top shells that are light and stiff. I would also incorporate ribs into the top shell to keep it stiff under shock loading (Bumps, etc...) This makes it much easier for the driver to drive and is much easier on the cells themselves. The original design had no ribs and would deform (especially in the back) when the car was in motion. Another thing that many teams do is to incorporate most of the bottom shell into the top shell as one piece. This makes the chassis easier to work with, and gives the shell more rigidity as a closed shape. It also gives more options for driver egress as you can incorporate a latching system to swing the topshell open. However, this might not be advisable with our current chassis design.

My design advice is to be creative, and not to use excessive safety factors (avoid the’ just in case’ doubling of safety factors–your car will end up too strong and too heavy). Testing will tell you if something needs to be redone.

Environmental Events 2002-2003

Apart from racing, we used the solar car to educate around Montreal about sustainability. Team iSun participated in the following environmentally focused events in 2002-2003.

Clean Air Day

Clean Air Day 2002 was a chance for the team to have the car on display in the heart of downtown Montreal. Thousands of spectators passed by to see the car, as well as other environmental projects sponsored by the city of Montreal, STCUM and Hydro Quebec.

McGill Envirofest

McGill Envirofest 2002 was an all day event on McGill Campus in the fall of 2002. The iSun car was featured along side a hybrid electric vehicle. The day was spent educating the McGill student body and members of the public about environmental issues in transportation.

Forum on Advanced Transport and Urban Mobility

The 2002 Forum on Advanced Transportation and Urban Mobility was an event sponsored by the province of Quebec and Hydro Quebec. Held in St. Jerome over a weekend in the fall, the event saw thousands of students and members of the public in attendance.

Quebec Minister for Energy

The Quebec Minister for Energy, Rita Dione-Marsolais came to see the car and the team at the ICP Global Technologies headquarters. She spent some time discussing the project and the future of renewable energy technologies with the team.

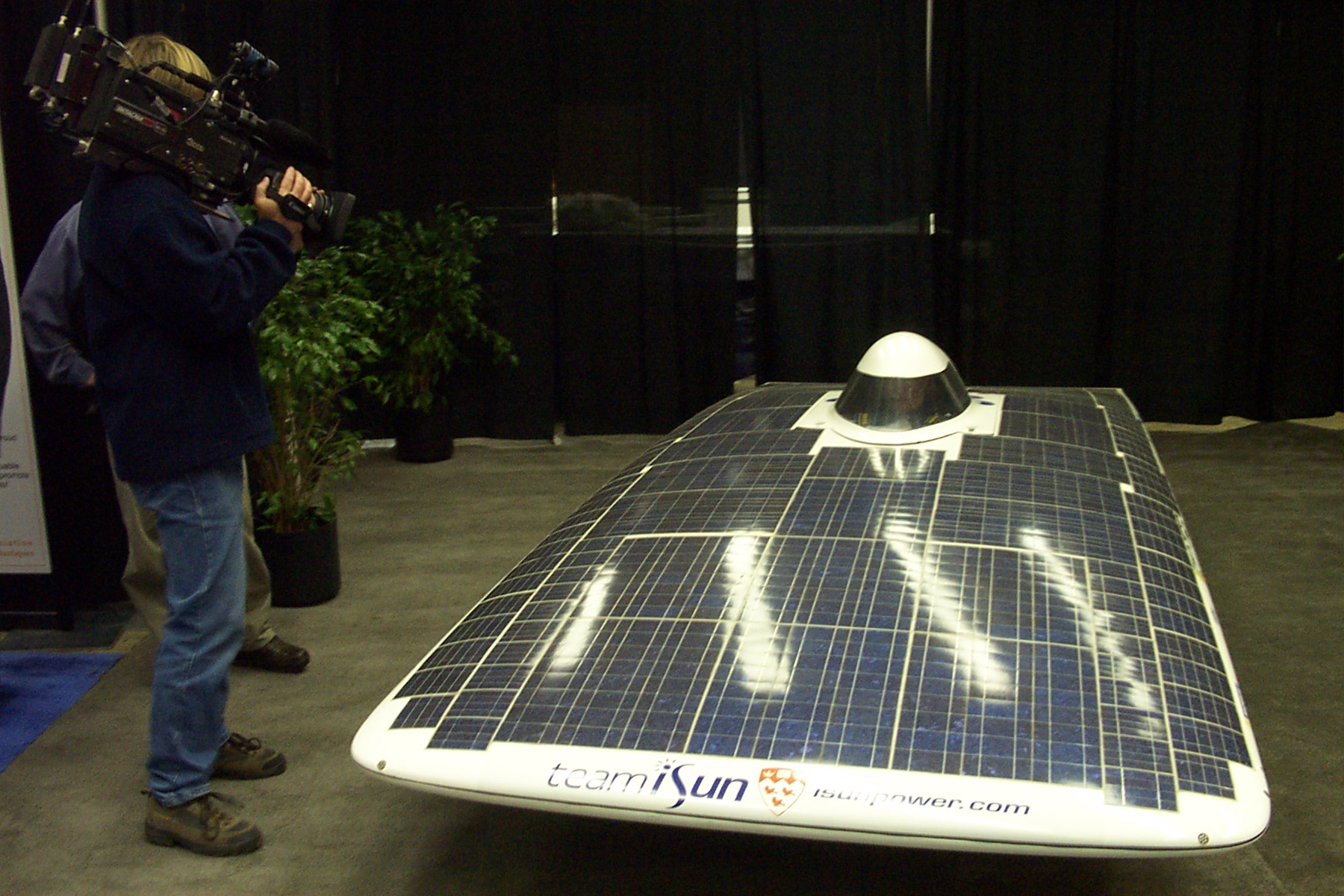

The 2002 Montreal International Auto Show

The 2002 Montreal International Auto Show hosted the team as a feature attraction. Team iSun was written up on the Auto show web site and in the Auto show Program. Organizers estimated attendance to the Auto show at well over 150 000 people. The team also appeared at the 4th annual Val d'OR Auto Show in the fall.

Expoplast 2002

Expoplast 2002 was a Canada wide plastics trade show held at Palais de Congres. Thousands of engineers were in attendance. Team iSun opened the event with the president of the Canadian Plastics Industry Association and had the car on display for the three days of the event.

Muscle Car Night

Muscle car night at the Big Orange brings hundreds of people and exotic vehicles every Thursday during the summer. Team iSun made a visit this year and was widely acclaimed as the winner in the exotic vehicle category.

Educational Initiatives 2002-2003

Salon de l’Education

Salon de l'Education is a large educational trade show held every year at the Palais De Congres in Montreal. Almost every high school in the Montreal area sends graduating students to the event. Team iSun was on hand with the car and the team to educate about renewable energy resources.

Institut Riene Marie

A local all girls school, Intsitut Riene Marie hosted Team iSun for a presentation on women in Engineering by Team member Emilie Fortier as well as an educational presentation on alternative energy.

Scout Centre Opening

Team iSun's presence at the opening of a new scout centre in Dorval in November 2002 allowed a whole troupe of scouts to experience solar power first hand. Team members gave a presentation on the project and conducted a demonstration drive of the car. In addition, Collaboration with students from CEGEP Marianopolis have helped to educate students about engineering and responsible stewardship of the environment.

Press Coverage 2002-2003

All these public relations events garnered the team a great deal of media exposure in print, as well as on TV and radio.

iSun solar car in McGill News.

In 2002/2003 the team was featured:

- On the BBC World News Homepage.

- In a 7 minute radio interview on CJAD.

- In the Journal De Montreal.

- In La Presse.

- On TVA news.

- On CFCF news.

- On CKMI news.

- On RDI Auto Show Coverage.

- On LDN news.

- On the cover of the May issue of Design Product News.

- In advertisements on CHOM for the Auto Show.

- In a feature article in Plastics and Mould Magazine.

- In the McGill Daily.

- In the McGill Tribune.

- In a feature article in the McGill Reporter.

- In a 3 page feature article in the McGill News.

- In a write-up in the Montreal International Auto Show program

- The American Solar Challenge program

- The combined distribution and exposure of the above media coverage is estimated at well over 5 million people. This is in addition to all the major press coverage gleaned from the American Solar Challenge.

Want to join the team? This was an add posted to bring in more talent.

Team iSun Sponsors

Team iSun was almost entirely funded by the support of our sponsors. Below are listed corporate and university sponsors that contributed to the solar car project in 2002-2003. Each sponsor donated technical advice, material, services, or financial and logistical support as indicated. In each case, the help provided proved invaluable to the team not only to design, build, and race the car, but also to promote the value of high technology studies and environmental awareness with the general public.

What follows is a complete list of Team iSun Sponsors as of May 2003.

- ICP Global - Solar cells, PPT's, Financial Support

- McGill Faculty of Engineering- Logistical and financial support

- Bombardier Aerospace- Engineering support, materials, financial support

- Bell Helicopter- Use of facility to build large composite parts, engineering support

- Eagle Picher-Li-Ion energy cells for the battery pack

- TD Friends of the Environment- Financial support

- YM- Financial support

- CMR Circuits- Printed Circuit Boards, financial support

- Summit Technologies- Printed circuit boards, financial support

- Formglas- Molds for composite parts

- Leesta- Machining services (Wheels, Suspension, Brakes, etc..)

- Tektronix- Oscilloscope

- Quebec Ministry of Energy- Financial support

- Thales Avionics- Financial and engineering support

- Quebec Ministry of Transportation- Financial support

- McGill Alumni Association- Financial support

- McGill Department of Mechanical Engineering- Financial and logistical support

- Cancino Technologies- Population of Printed Circuit Boards

- Hydro Quebec- Financial support

- Infolytica- Financial support

- McGill Department of Electrical Engineering (MUDN)- Financial and logistical support

- Canadian Plastics Industry Council- Financial support

- EVAC (Natural Resources Canada)- Financial support

- Aerospace Welding- Welding on titanium suspension parts and roll cage.

- PTC- ProEngineer Design Software.

- NMF-Aluminum Stock for wheels, Rear suspension, steering, brakes.

- Aerocontrolex- Steering components and system troubleshooting support

- Titanium Industries- Titanium stock for suspension.

- Students Society of McGill University (SSMU)- Financial support

- 3M- Tapes, and other composite work materials.

- CCS- PIC Compiler.

- Excell Batteries- Auxiliary batteries

- Loctite- Locking Compounds, Lubricants and Resins.

- Motion Industries- Bearings

- Fischer Connectors- Electrical connectors

- Harbour Industries- High performance wire

- Ingersoll Rand- Financial support

- Suncore Energy Foundation- Financial support

- Asystel- Printing services

- NSK- Bearings.

- Plascore- Nomex Honeycomb core for composite work.

- Deft- Paint and Primer and Gelcoat for molds and parts.

- Cooper Industries- Tools.

- Lyreco- Stationary

- McGill Physics Department- Financial support

- Iscar- Machining supplies.

- JNFD- Machining services

- Michelin- Solar Car Tires

- Fibercote- Mould release and sealing agents.

- Airtech- Composite bagging, breather and tape.

- Hewlitt Packard–Workstation

- Integris Metals–Metal Stock

- Minicut International–Machining Supplies

- Alouette–Financial support

- Nelcor Technologies–Machining services

- Mitutoyo–Measurement equipment

- Aurora Rod-Ends–Rod-ends

- Brentagg–Chemicals and cleaners

- McGill Computer Store–Computer Equipment

- Fluke–Multi-Meters

- Molex- Connectors

iSun snaking through farm country in the American Solar Challenge 2003.

Overall my experience with solar racing while at McGill was one of the most influential experiences of my life. I learned the power of persistence and that dreams can be made real through hard work. Thank you Gabe, Matt, Nick, Phil, Daniel, Matthieu, Matt, John, Joel, Emilie and everyone else. Love you guys.

What questions do you have about Solar Racing or my experience building the iSun car?